3D Printed Fabric

Techniques for Design and 3D Weaving Programmable Textiles

Abstract

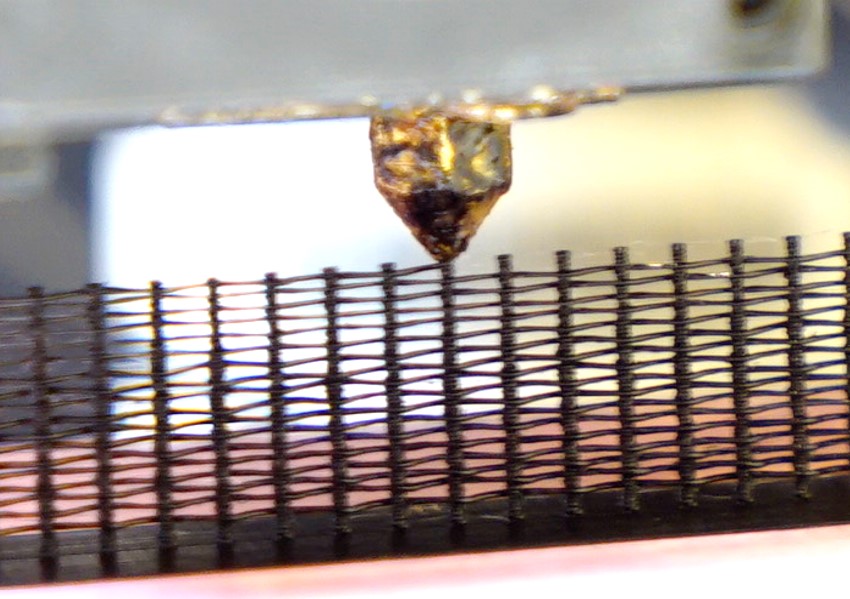

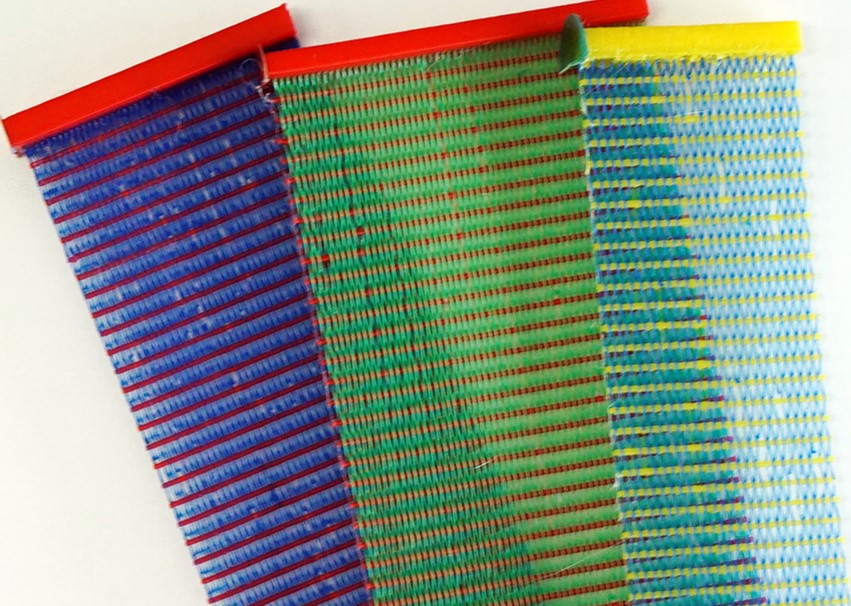

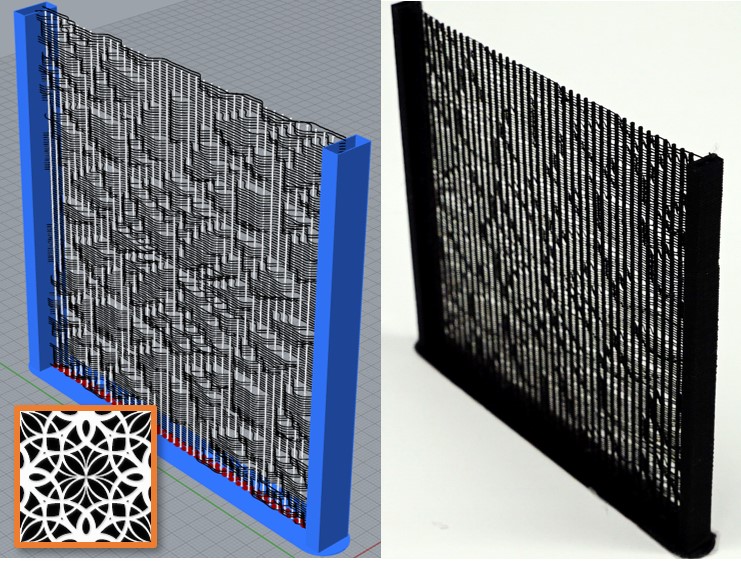

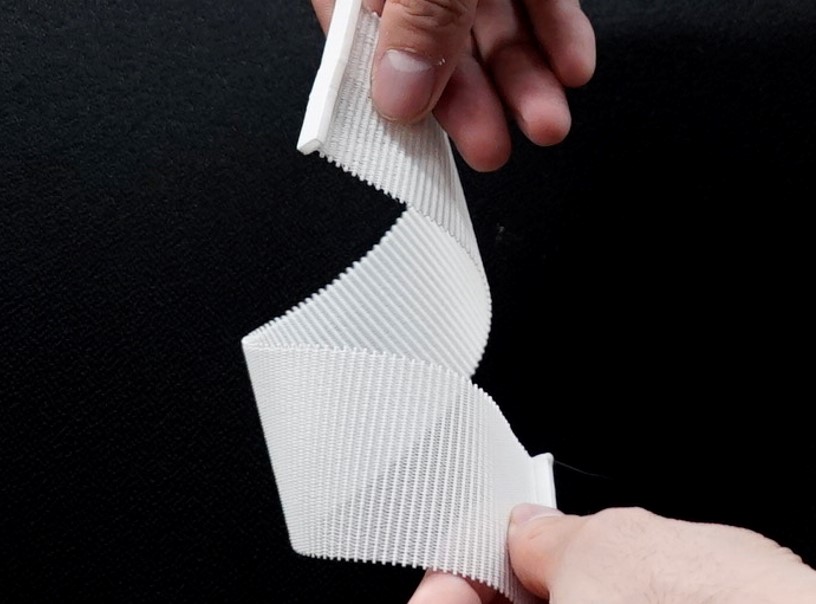

We present a 3D printing technique for a soft and flexible textile fabrication using a consumer grade fused deposition modeling (FDM) printer. By controlling the movement of the print header, the FDM alternately weaves the stringing fibers across a row of pillars. Owing to the structure of the fibers, which support and strengthen the pillars from each side, a thin and flexible sheet of fabric can be printed upright while the fibers are being weaved. In addition, this technique enables users to employ two material colors to design a pattern and prototype an interactive object through a variety of off-the-shelf material properties such as conductive filament. We detail a technique for weaving a textile and introduce a list of parameters that enable users to design various textiles. We demonstrate examples to show the feasibility of our approach and numerous applications to integrate printed textiles in a custom object design.Video

Images